Not known Details About Sheet Metal Laser Cutter

Wiki Article

On the subject of fashionable producing, the precision and efficiency of laser reducing technological innovation are truly recreation-transforming. Laser slicing devices have revolutionized industries by furnishing a method of chopping supplies with unparalleled precision. In the event you’ve at any time marveled for the intricate types on metallic or wondered how complicated designs are created so seamlessly, it’s frequently the get the job done of the industrial laser slicing equipment.

Permit’s get started with the fundamentals: a laser cutter is really a Instrument that utilizes a laser beam to chop elements. This beam is extremely concentrated and generates high temperatures to melt or vaporize the fabric, building exact cuts. In contrast to common procedures, which might use mechanical blades, a laser cutter provides a degree of accuracy that is sort of unmatched. Consider seeking to carve a fragile sample having a hammer—Evidently, a laser cutter is a great deal far more refined!

Industrial laser cutting usually takes this technology to another amount, providing methods for giant-scale operations. These machines are built to take care of significant resources and significant generation volumes, ensuring that even essentially the most demanding jobs are done with high performance. Think about it as the difference between using a precision knife for delicate paper crafts and a strong observed for chopping as a result of thick Wooden.

The Facts About Laser Cutting Technology Revealed

In the world of CNC laser chopping, the “CNC” means Laptop or computer Numerical Command. This engineering permits automatic and very exact cuts by subsequent electronic models. Should you’ve at any time utilised a pc to attract and then witnessed that drawing come to daily life, CNC laser reducing performs in a similar way, translating electronic models into Actual physical cuts. It’s like aquiring a virtual designer While using the precision of a laser.

In the world of CNC laser chopping, the “CNC” means Laptop or computer Numerical Command. This engineering permits automatic and very exact cuts by subsequent electronic models. Should you’ve at any time utilised a pc to attract and then witnessed that drawing come to daily life, CNC laser reducing performs in a similar way, translating electronic models into Actual physical cuts. It’s like aquiring a virtual designer While using the precision of a laser.What Does Sheet Metal Laser Cutter Do?

Precision laser cutting is just not nearly producing cuts; it’s about generating them appropriate each time. The laser may be altered to achieve different depths and widths, guaranteeing that every Slice is exactly wherever it should be. This really is important for purposes wherever even a slight deviation may lead to substantial concerns. Visualize it as a surgeon’s scalpel, exactly where precision is not merely significant but Definitely important.

Precision laser cutting is just not nearly producing cuts; it’s about generating them appropriate each time. The laser may be altered to achieve different depths and widths, guaranteeing that every Slice is exactly wherever it should be. This really is important for purposes wherever even a slight deviation may lead to substantial concerns. Visualize it as a surgeon’s scalpel, exactly where precision is not merely significant but Definitely important.Laser cutting products is available in many varieties, Every single tailor-made to particular needs. No matter whether You'll need a smaller desktop model for pastime initiatives or a large industrial equipment for manufacturing unit use, there’s a laser cutting Option available for you personally. These equipment vary in electrical power, pace, and capabilities, so it’s essential to pick the appropriate one particular to your unique software.

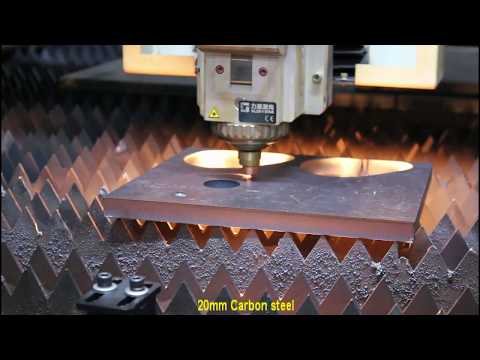

Sheet metal laser cutters undoubtedly are a Particular category of laser cutting devices created specifically for slicing metallic sheets. They are really commonly Utilized in industries ranging from automotive to aerospace because of their power to deal with metallic with precision and pace. Photograph a sheet of steel similar to a blank canvas, plus the laser cutter as being the artist who produces complicated and beautiful designs with incredible accuracy.

Laser slicing expert services are An additional important aspect of this technological know-how. Not Absolutely everyone wants to take a position in their own personal laser chopping equipment, particularly if they only will need occasional cuts or lack the Place for this kind of products. Many firms provide laser cutting products and services in which you can send your layouts and possess them Slash with high precision. It’s like outsourcing your artwork to a talented professional.

Laser reducing units combine a variety of components to deliver the specified final results. From the laser source into the chopping bed, plus the Handle software program, every Component of the technique functions with each other to make sure a flawless Procedure. It’s a little bit similar to a symphony orchestra, the place Every single musician has a particular part, and only by working collectively do they make a harmonious functionality.

In regards to laser chopping know-how, the evolution has become swift and impressive. Initially made use of mostly for reducing metals, these devices now take care of a wide array of resources including plastics, wood, and even fabrics. This flexibility makes laser slicing engineering a important Software in countless industries. Visualize aquiring a Swiss Military knife which can take care of practically any content—That is what modern-day laser slicing know-how delivers.

The accuracy of laser reducing machines is truly exceptional. They can Slash components to in just microns of the supposed structure, guaranteeing that even one of the most intricate details are preserved. This amount of precision is particularly important in industries where exact measurements are crucial. Think about it given that the difference between a tailor-made suit and off-the-rack clothing—the healthy is just fantastic every time.

Facts About Sheet Metal Laser Cutter Revealed

Another benefit of laser cutting know-how is its performance. Unlike regular slicing techniques That may require many actions or instruments, laser chopping normally completes the activity in one go. This not just quickens production but will also minimizes product squander. It’s like aquiring a superior-pace practice that will get you to the place speedily and competently with no avoidable stops.While in the context of industrial applications, the robustness of laser chopping machines is important. These devices are designed to endure the calls for of continual operation, typically functioning 24/7 in high-volume options. Their sturdiness makes sure steady overall performance and trustworthiness, discover here that is essential for sustaining output schedules. It’s like getting a hefty-duty truck that reliably delivers items working day soon after working day.

Among the list of remarkable elements of laser chopping is its power to deliver clean up and exact edges. This lessens the need for publish-processing, which include sanding or ending, which can be time-consuming and dear. The result is a smooth, finished product or service That usually requires minimal extra perform. Picture ending a craft project without any glue learn more spills or rough edges—it’s that clear!